Backwash type precision filtration

BackWashable Macro Filter

Characteristics of MacFilter

The technology for separating micro-particles in the current market includes a method using filter media (Sand or multi-layered filter media), an auto strainer method using a precision screen, and a method of forming pores by pressing with fiber yarn in addition to the cartridge filter method.

However, common problems with these methods are that fouling can be solved by releasing pores during backwashing, but the instantaneous throughput is good due to excessive backwashing depending on the raw water, but the total throughput is much less than expected and the energy cost is high due to the excessive backwashing process.

MacFilteris a stable and powerful product that dramatically improves the loss caused by the backwash process by introducing an instant backwash process by air to overcome the shortcomings of the existing products.

MacFilter SYSTEMis a filtration treatment technology that applies Macro Filter. Compared to existing filtration devices, it is a highly integrated filtration system with large processing capacity and easy cleaning.

High Flux Macro Filteration

Turbo Backwashing

MacFilter applied fields

• Effluent filtration facility (replaces sand filter)

• Pretreatment of advanced filtration (UF, RO, etc.) system

• Incineration ash treatment in pyrolysis incineration plant

• Farm water purification, reuse

• Desalination pretreatment

• Tunnel wastewater, wastewater treatment

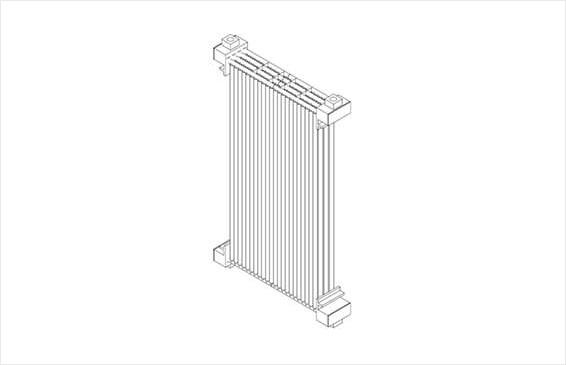

MacFilter

Macro Filter

MacFilter Module Specification

| TYPE | Submersible Macro Filter |

| Module Frame Material |

ABS |

| Pore Size | 2~10μm |

| Element Material | PVDF |

| Maximum Temperature |

50 ℃ |

| pH range | 3 ~ 13 |

| Operation pressure | -6 ~ 0 kgh / cm2 |

| Operation Flux | 80~500LMH |

TMF Module Specification

| MODEL | Size WxLxH(mm) | FLOW RETE (m3/day) |

|---|---|---|

| MAF 24D | 650 x 1,000 x 1,800 | 72 ~ 86 ~ 230 |

| MAF 36D | 650 x 1,050 x 1,800 | 108 ~ 125 ~ 345 |

| MAF 44D | 650 x 1,700 x 1,800 | 132 ~ 153 ~ 422 |